Why choose a synthetic oil?

Synthetic oils are thermally stable, have a better viscosity film strength and a better ability to occupy space between two metal surfaces under pressure or heat.

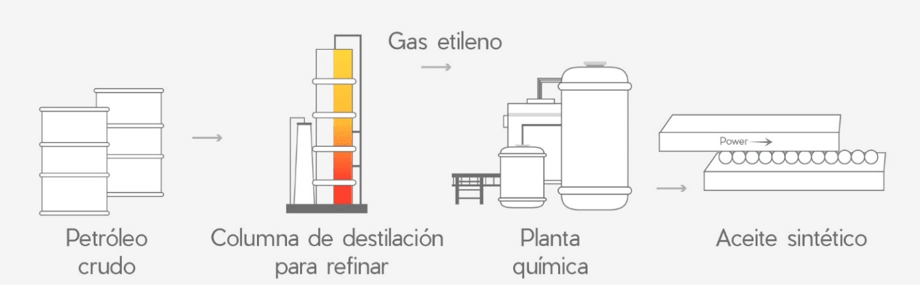

As we know, lubricant oil is obtained from the refining of petroleum through a process of atmospheric distillation of crude oil.

Synthetic oil, in addition to refining, goes through a series of processes to remove unwanted components. These processes can be dewaxing, de-asphalting and hydrogenation. This increases the quality of the oil depending on the treatment and its intensity.

Image 01. Synthetic oil

Image 01. Synthetic oil

Synthetic oils are more uniform, which makes them thermally stable and tend to have a stronger lubricant film at higher temperatures. This resistance indicates the ability of a lubricant to occupy space between two metal surfaces under pressure or heat.

Image 02. Synthetic oil

Image 02. Synthetic oil

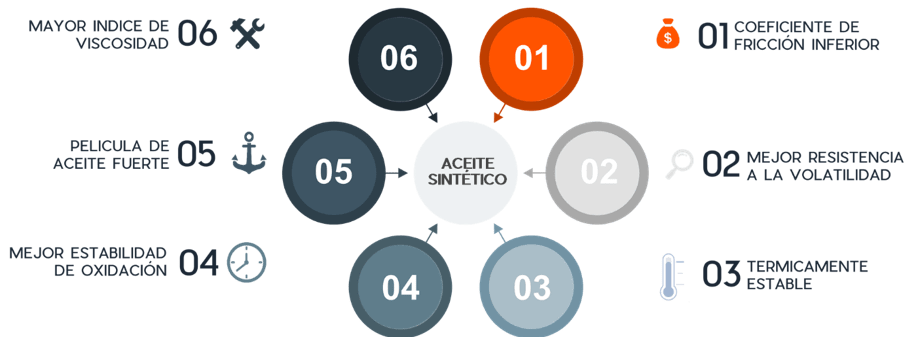

Synthetic oil characteristics.

Unlike the mineral oil which its main benefit is to be cheaper, synthetic oils properties provide a great variety of benefits:

Image 03. Advantages of synthetic oil

Image 03. Advantages of synthetic oil

Why choose a synthetic lubricant?

In the industry we know that there are no two processes that are identical, given that each operation has its unique conditions. Synthetic lubricants, being more molecularly uniform than its mineral counterparts, have a series advantages such a thermal stability.

The main advantages that synthetic oils offer are:

Synthetic oil is usually more expensive than mineral oil by the liter. However, given that lubrication periods are longer, its lower consumption can make it the cheaper alternative.

93% of lubrication professionals would buy a lubricant with a high quality (synthetic) base oil at a higher initial price rather than a lubricant with a low quality (mineral) base oil at a lower initial price, according to a recent survey on machinerylubrication.com.

SHARE ARTICLE

Join our newsletter

Get the newest articles and be up to date on everything that happens on the lubrication world.