Industrial oil, properties and characteristics

Without industrial lubricating oils almost all machines would be damaged by wear and tear and stop working. Lubrication is essential for all processes in the industrial sectors

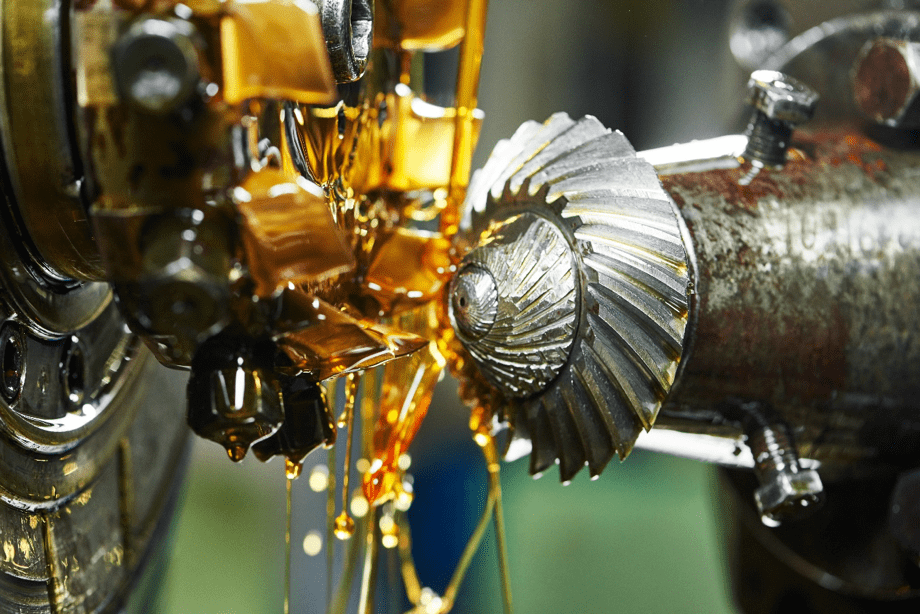

Lubrication is considered as vital a part of the machine as any of its mechanical elements. Bearings, gears, and the other elements that make up any machine today must be carefully designed and precisely manufactured, with the very best materials in order to meet the demands of modern high-speed production. But these same parts without proper lubrication would quickly show wear and tear and soon cease to function.

Lubrication is a necessary for the operation of all equipment and especially industrial machinery. With new chemical products and processes emerging constantly, the world of the industrial oils and the lubricant industry is advancing rapidly.

Getting to know the latest in industrial oil technology will help you to improve your industrial processes.

Lubricating oil properties

Lubricating oils are essentially composed of two parts: a base oil and additives.

The base oils determine most of the “Lubricanting Oil” properties, such as viscosity, resistance to oxidation and pour point. These bases themselves can be either mineral (a product of petroleum) or synthetic.

Image 01 Industrial oil

Image 01 Industrial oil

Applications and characteristics of industrial oil

Industrial lubricants meet a wide range of applications from the most economical lubricating oils for old machinery to those that meet the requirements for the most precise equipment. The main applications with their own variants for which lubricants oils should be selected are the following: gears, bearings, hydraulic systems, internal combustion engines and metalworking fluids.

The main properties that lubricating oils should have in order to be considered good, are the following:

SHARE ARTICLE

Join our newsletter

Get the newest articles and be up to date on everything that happens on the lubrication world.