Discover the importance of lubrication

Adequate lubrication reduces maintenance costs by 60%, considerably reducing accelerated wear of equipment.

In order to achieve the efficient operation of industrial machinery, it is very important to know the basics of tribology (the science that studies friction, wear and lubrication) since lubrication is transcendental for industrial maintenance. It is a field that, if applied correctly, would help increase productivity in industrial processes and would generate great savings. In spite of this, lubrication has been relegated in most companies. According to several studies carried out between 2014 and 2018, 92% of the plants have lack of adequate lubrication procedures and 74% of the plants do not use lubricant analysis as a monitoring tool.

What is lubrication?

In mechanical applications, it is common to have friction and wear. These bring negative consequences that directly affect the companies' pockets.

Friction causes energy dissipation and wear is the main cause of material loss. Avoiding or reducing them would bring energy savings and great benefits to the industry.

The most effective way to counteract friction and wear is through lubrication. Its purpose is to introduce a lubricant film that facilitates the sliding that takes place between contact surfaces in the mechanical elements of machinery.

What must be taken into account?

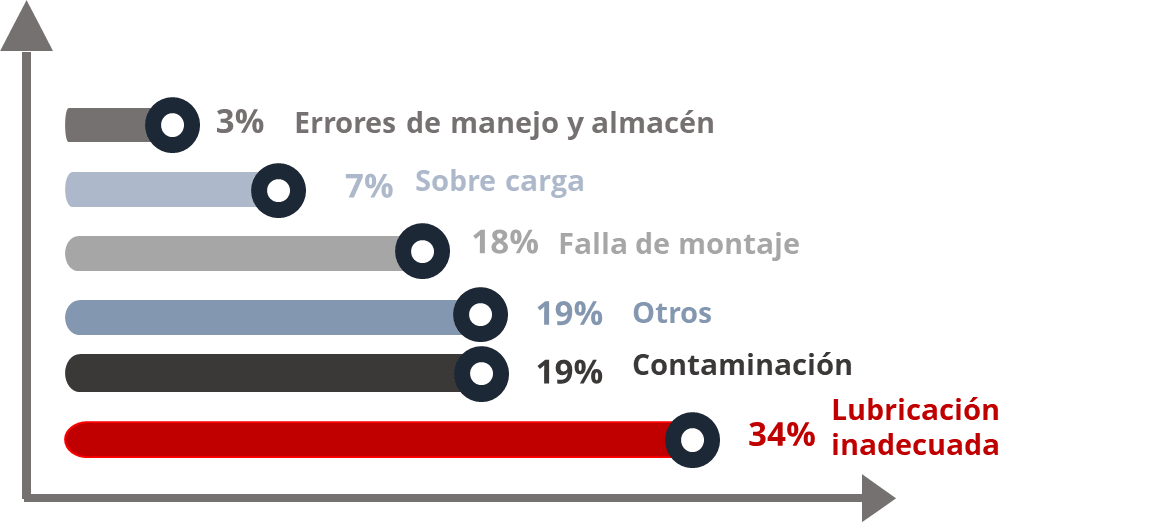

Of the entire budget for a maintenance department, usually just 2% is allocated to lubrication. However, out of the total number of mechanical failures about 34% are caused by inadequate lubrication.

Chart: Mechanical failures in industry

Chart: Mechanical failures in industry

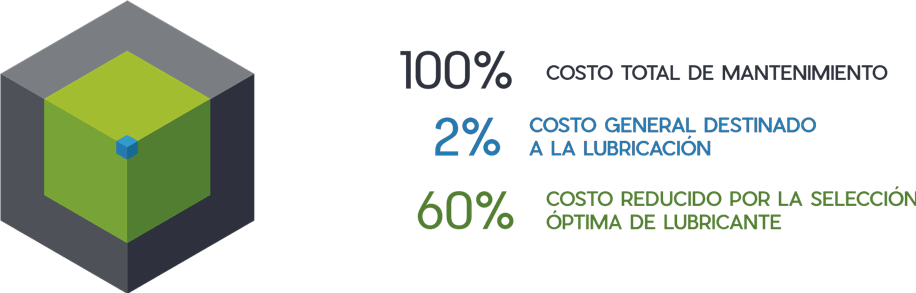

If this budget was properly allocated maintenance costs would decrease by 60%, significantly reducing accelerated wear and tear on equipment and generate savings on spare parts, which would increase process productivity considerably because equipment availability would increase.

Image 01. Importancia de la lubricación

Image 01. Importancia de la lubricación

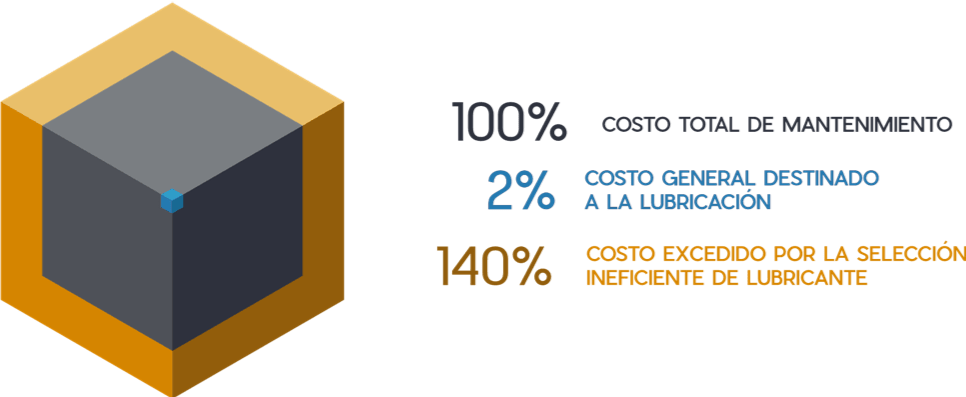

Otherwise, if the 2% is invested in the wrong lubricant, the costs may increase by up to 140%.

Image 02. Importance of lubrication

Image 02. Importance of lubrication

How to achieve optimal lubrication?

Having a lubrication plan and allocating the budget to the right product can lead to significant improvements and at the same time reduce lubrication problems.

The change needed to achieve proper lubrication is embodied in a new concept from Interlub called Smart Touch. This system aims at maximizing the benefits of the properties of lubricants through the implementation of good practices and excellence in lubrication.

This process contemplates the lubrication process as a sequence of stages in which people, procedures and auxiliary lubrication material intervene in a coordinated manner, with the focus placed on achieving the main objective: to provide added value to the maintenance of our customers.

The objectives of the SmartTouch® program provided by Interlub Group are achieved through work and improvements in the following areas:

S.M.A.R.T. training

Is divided in five stages. First the adequate lubricant is selected, with the help of a specialized technician for the application depending on the conditions and the mechanism. Then, the aim is to improve productivity, avoid unscheduled downtime, reduce spare parts costs and/or environmental impact through lubrication. For this purpose, we apply a lubrication program that we design to be ideal for the different mechanical elements. This unique program seeks to satisfy our customer's needs, and we constantly report the monitoring of critical variables, documenting key indicators and providing feedback to the technical consultant.

SHARE ARTICLE

Join our newsletter

Get the newest articles and be up to date on everything that happens on the lubrication world.